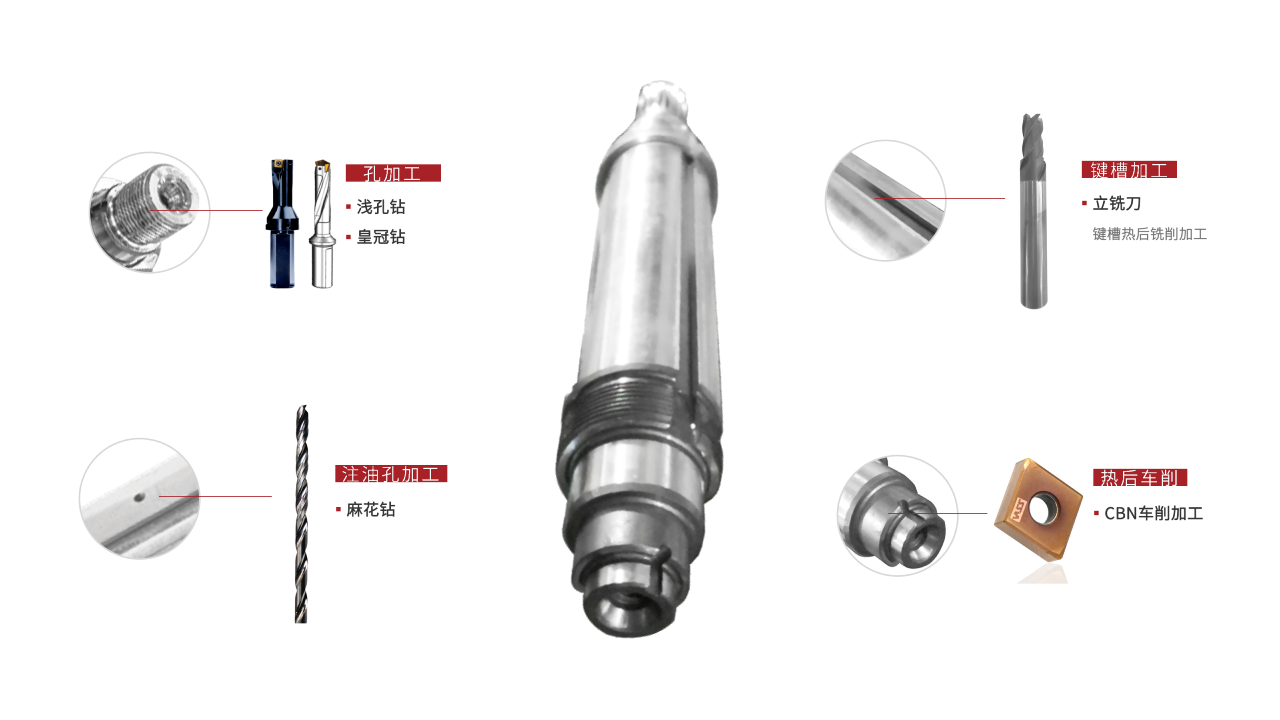

High-efficiency machining solution for new energy vehicle drive motor shafts

Drive motor shafts are subjected to alternating stresses such as torsion, shear, tension, compression, and impact during operation, and are subjected to large loads and torques. At present, other high hardness materials such as 20CrMnTiH materials are commonly used in the manufacture of motor shafts. In addition, the connecting parts at both ends of the shaft body need to be heat-treated to meet the requirements.

WSS offers turning, milling and holemaking tools for the complete machining of motor shafts with higher stability and reliability, which not only meets the high dimensional precision requirements for oil-filled holes, keyways and shallow holes in motor shafts, but also provides high surface quality after CBN hard turning.

Processing before heat treatment:

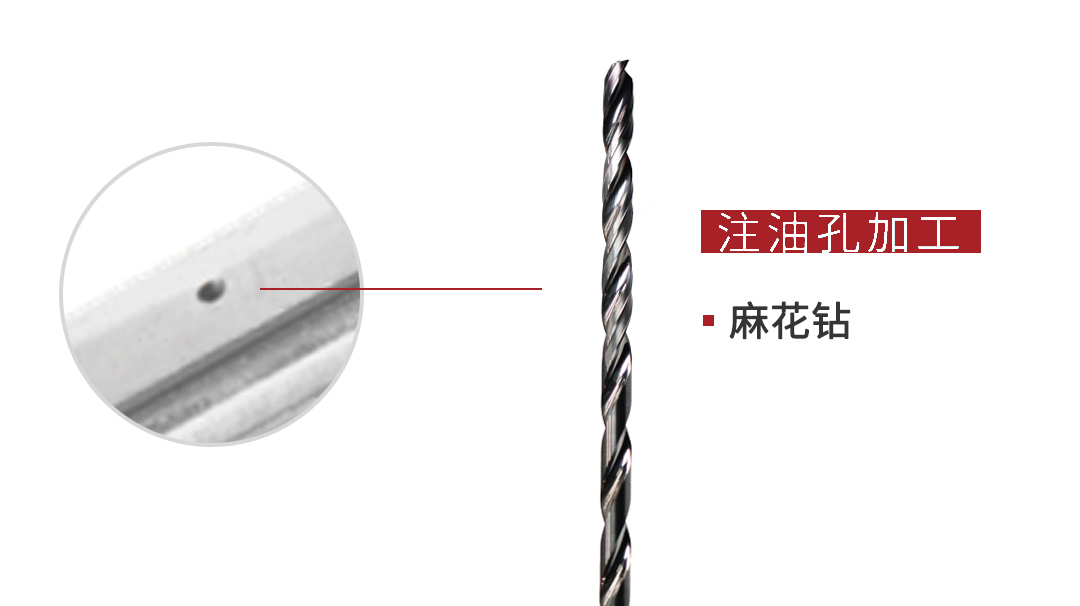

Oil Filling Hole Processing

twist drill

Tool Features:

Polished chipformer surface for enhanced chip evacuation

High reliability and reduced burrs

High drilling efficiency and process stability

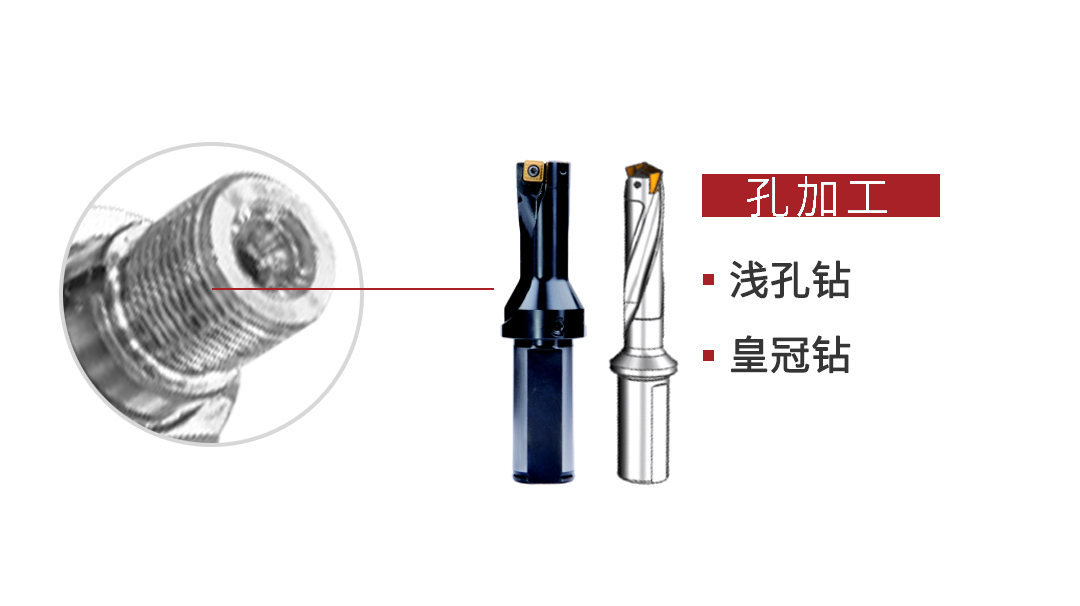

Hole Processing

Shallow hole drilling

Crown drilling

Tool Features:

High drilling efficiency, low cost per hole

Good chipbreaking performance, smooth chip removal, no

tangling of the toolholder

Internal cooling channels for efficient cooling and

lubrication

Easy and quick tool tip change, short downtime

Heat-treated post-processing:

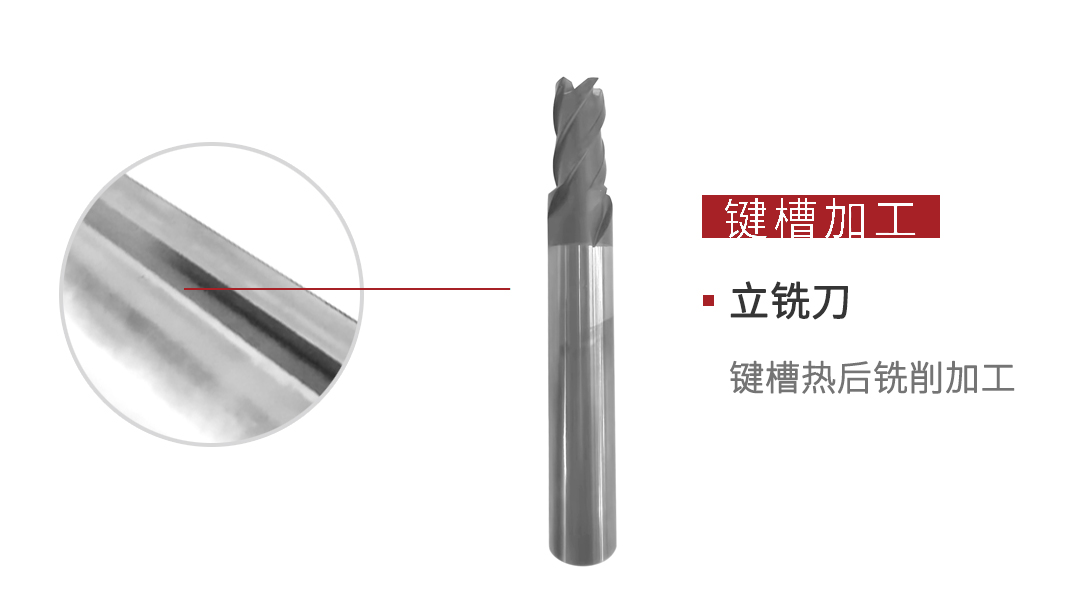

Keyway machining

End Mills

Keyway Hot Post Milling

Tool Features:

Suitable for milling hardened high hardness steels

High metal removal rate

High milling surface quality

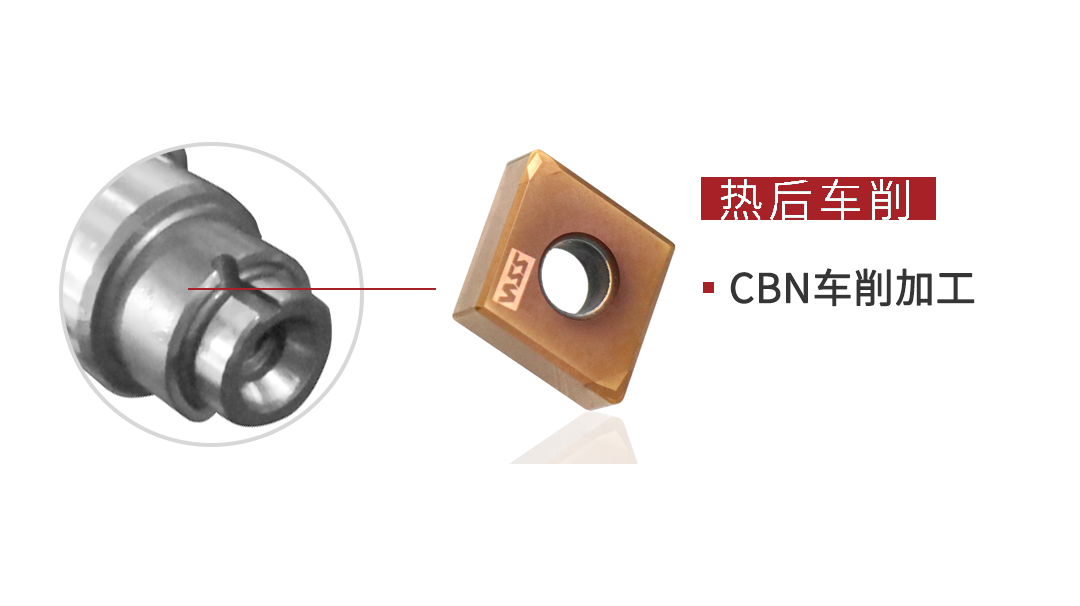

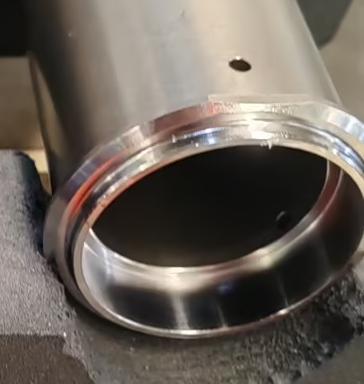

Turning after heat

CBN Turning

Tool Features:

Better chipping resistance for coated tools

Intermittent turning of end faces with high surface

quality

Achieve higher line speed turning, higher machining efficiency

More on-site solutions:

For roughing and finishing of motor shafts after heat treatment. WSS has a line of CBN tools with consistent machining performance and longer life.

WNGA080408 Standard tool for roughing 1mm bore depth of cut

CCGW060204 Standard Tool Finishing Bore

VNGA160404 Standard tool for machining external cylinders